Engineered timber for superior performance

Glued Laminated Timber is an engineered timber product manufactured by gluing together smaller pieces of stress graded and seasoned timber typically finger-jointed into continuous lengths. Southern Pine, Douglas Fir-Larch, Alaskan Yellow Cedar, Ash, Chestnut, Oak and Spruce are some of the available species.

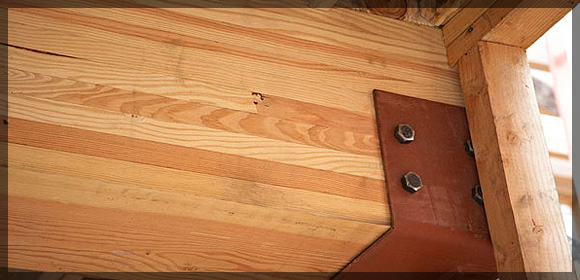

Glulam offers high strength and design flexibility, allowing long spans, curved profiles, and custom shapes that are difficult to achieve with solid wood. Its stability and predictable performance make it suitable for beams, columns, arches and structural frames in both residential and commercial projects. It is also valued for its aesthetic appeal, sustainability and efficient use of timber resources.

Prior to gluing, the laminates are dressed to exact, uniform thickness and clamped under constant pressure until the glue cures. The members are then planed, cut to size and can be coated with a water repellent sealant. Glulam is extremely stable and will not shrink, crack or shake, and it can be easily treated with decorative finishes. Stronger than solid timber, its strength and performance are highly reliable.

Engineers tend to love them as they are very uniform, stable and predictable which suits their structural analysis demands. For this reason, Glulam's are often used in large scale building projects such as public buildings and commercial venues. They are also well suited for modern, contemporary buildings because exact shapes, curves, radii and specific sections can achieve a very crisp and sharp look. Glulam's are often referred to as the timber equivalent of steel beams.